0

Jahre Erfahrung

0

Jahre Rahmenverträge in der Petrochemie

0

Tonnen stahl auf Lager, um handlungsfähig zu sein.

0

produzierte MWh durch eigene PV-Anlage

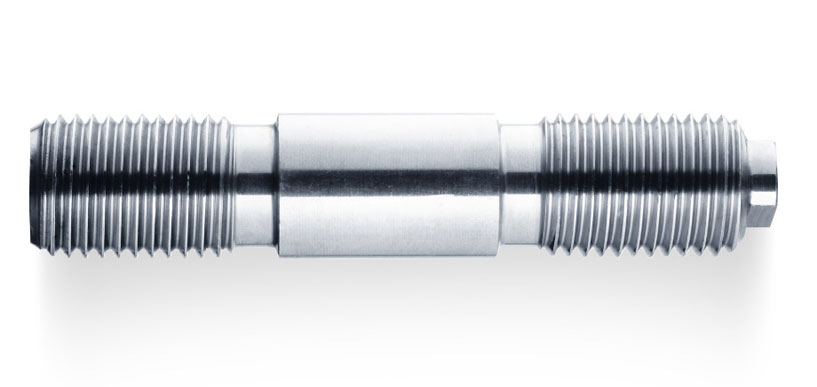

Wir stehen für garantierte Leistungsbereitschaft. An unsere Produkte stellen wir denselben Anspruch. Als Hersteller von Sonderschrauben und Verbindungselementen bieten wir Ihnen konstant kompromisslose Qualität und beste Performance.

Nehmen Sie direkten Kontakt zu uns auf.